Elevating Electronics: The Significance of PCB Cleaning with TouchPad Electronics

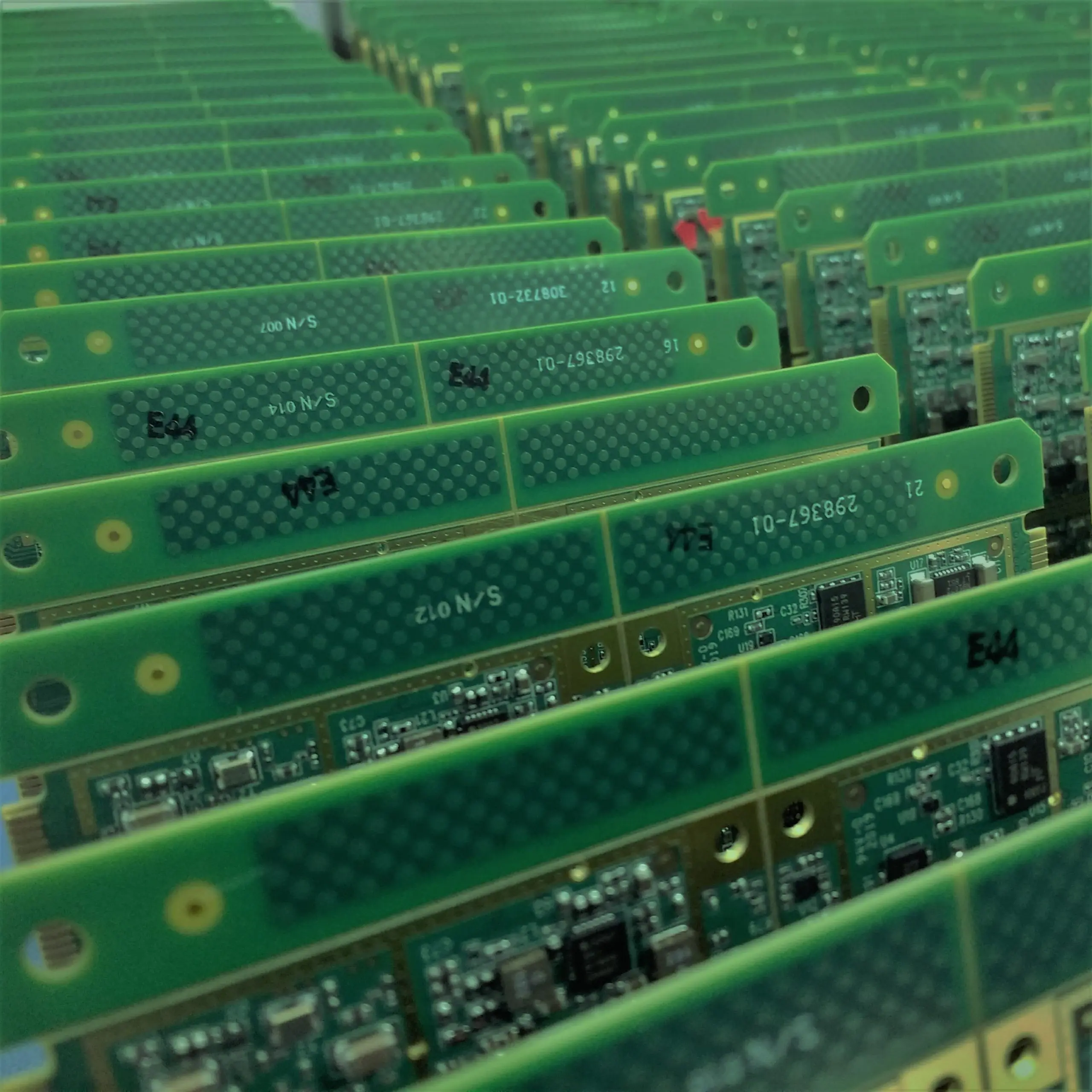

In the dynamic realm of electronics, the cleanliness of Printed Circuit Boards (PCBs) stands as a technological keystone for reliability and performance. At TouchPad Electronics, we recognize the pivotal role that PCB cleaning plays in ensuring optimal functionality and longevity. In this refined blog post, we dive into the importance of PCB cleaning, the potential repercussions of neglecting it, and how TouchPad Electronics emerges as the premier partner for achieving pristine PCBs.

Unpacking the Importance of PCB Cleaning

Precision Flux Residue Management:

Excess flux residue, a byproduct of the soldering process, poses a significant risk to PCBs. It can lead to electrical shorts, corrosion, and compromised insulation resistance. TouchPad Electronics prioritizes precision flux residue management, ensuring the removal of potential hazards and fortifying the integrity of your circuitry.

Contaminant-Free Prowess:

Throughout the manufacturing journey, PCBs accumulate contaminants like dust, grease, and handling residues. Our meticulous cleaning processes eliminate these contaminants, creating a pristine surface that optimizes electrical performance and guards against issues like reduced insulation resistance.

Electrical Harmony and Reliability:

Residues on PCB surfaces increase the likelihood of electrical shorts, impacting the circuit’s functionality and risking device failure. TouchPad Electronics is dedicated to ensuring electrical harmony and reliability, mitigating the risk of issues that could compromise the dependability of your electronic components.

Corrosion Prevention Strategies:

Corrosion, a potential consequence of unaddressed flux residues, can jeopardize the integrity of solder joints and conductive traces. Our proactive cleaning approach serves as a defense mechanism, preventing corrosion and extending the operational lifespan of your electronic devices.

The Fallout of Neglecting PCB Cleaning

Reliability Erosion:

PCBs left with contaminants are susceptible to electrical issues, resulting in reduced reliability and an increased likelihood of product failure. Neglecting cleaning can lead to escalated warranty claims and reputational damage for your brand.

Performance Deterioration:

Contaminants and residues hinder PCB performance, impacting signal integrity and overall device functionality. Devices with compromised performance face compatibility issues and heightened customer dissatisfaction.

Elevated Maintenance Costs:

Unclean PCBs may require more frequent maintenance and repairs, translating to elevated operational costs. TouchPad Electronics’ commitment to quality thorough cleaning contributes to component longevity, minimizing the need for costly interventions.

TouchPad Electronics: Your Partner in Pristine PCBs

Cutting-Edge Cleaning Facilities:

Our facilities feature state-of-the-art machinery and eco-friendly cleaning solutions, ensuring the highest industry standards are met. TouchPad Electronics utilizes advanced equipment for thorough and efficient cleaning, elevating your PCBs to unparalleled levels of cleanliness.

Tailored Cleaning Solutions:

Recognizing the diverse needs of different PCBs, our expert team crafts customized cleaning solutions for your unique application. From environmentally conscious water-based cleaning to precise ultraviolet curing to protect unique component features, we possess the expertise to deliver optimal results. We are able to customize your specifications to a custom micrograms of dirt molecules/sq. inch to ensure customers are satisfied when the stakes are high.

Exceeding Industry Standards:

Our commitment extends beyond meeting industry standards; we strive to exceed them. When you choose TouchPad Electronics, rest assured that your PCBs will not only meet but surpass the stringent requirements of your target market.

Collaborative and Sustainable Practices:

We believe in transparent communication and collaboration. Our team collaborates closely with yours, offering insights to optimize the cleaning process. TouchPad Electronics is dedicated to sustainable practices, minimizing environmental impact while ensuring the highest level of cleanliness for your PCBs.

Conclusion

In the competitive landscape of electronics manufacturing, PCB cleaning emerges as a non-negotiable step toward unlocking the full potential of your electronic devices. TouchPad Electronics, with its state-of-the-art facilities, customized solutions, and commitment to excellence, stands as your unwavering partner in achieving impeccable PCB cleanliness. Whether building prototype PCB assemblies or production, we will deliver high quality every time. Choose TouchPad Electronics, and elevate your electronic products to new heights of reliability, performance, and customer satisfaction. Get your quote within 48 hours for your next unique PCB Assembly.