ERSA Versaflow 3/45 for Through-Hole Efficiency

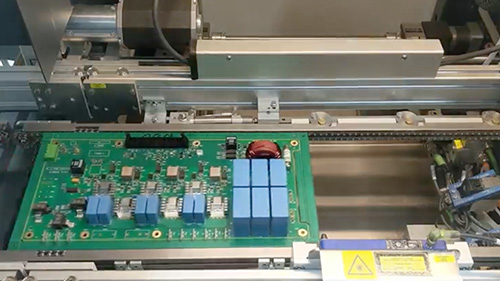

TouchPad’s through-hole capability is augmented by the Ersa VERSAFLOW 3/45, a complete selective soldering system. This machine combines fluxing, preheating, and soldering modules into one compact unit for consistent through-hole component application. The level of automation provided by this technology is one of the many elements of our new facility that has enabled us to expand into mid-volume production.

Assemblies are staged for solder and begin by entering the fluxing module. The VERSAFLOW 3/45 was designed to apply flux efficiently and precisely using drop-jet fluxing techniques. Two small nozzles deposit flux onto solder areas without any unwanted overspray. This method allows for contaminants and oxides to be removed from solder areas before assemblies pass through the heating and solder modules. With any potential contaminants removed, heat is distributed more evenly, and board continuity is ensured after the solder process.

After the assembly has passed through the flux module, it is conveyed to the preheating module. Preheating assemblies before they enter the solder module increases the adhesion of materials at solder joints. This increased adhesivity produces more consistent and robust solder joints during the solder phase. The combination of induction and infrared heaters guarantee assemblies are thoroughly heated on both sides. Smart heating allows heat temperatures to be adjusted over time to control board temperature throughout the process.

Once sufficiently preheated, the board enters the soldering module. This machine comes equipped with dual pot lead and lead-free ready technology, allowing for the single wave solder module to be utilized to its fullest potential. The onboard software allows for full CAD and board schematic import that our technicians use to create completely customizable and highly versatile wave paths. The complete automation the Ersa VERSAFLOW 3/45 provides facilitates the formation of accurate and consistent solder joints on every single assembly. Throughout the full solder process, live camera feed from the machine is monitored by technicians to ensure quality and optimize production flow.

The combination of all these features allows full control of the assembly through-hole solder process. To learn more about this advanced technology, watch the video below showcasing this versatile machine: https://www.linkedin.com/posts/touchpad-electronics-llc%2E_touchpad-electronics-ersa-versaflow-345-activity-6752626939149770752-wHrh