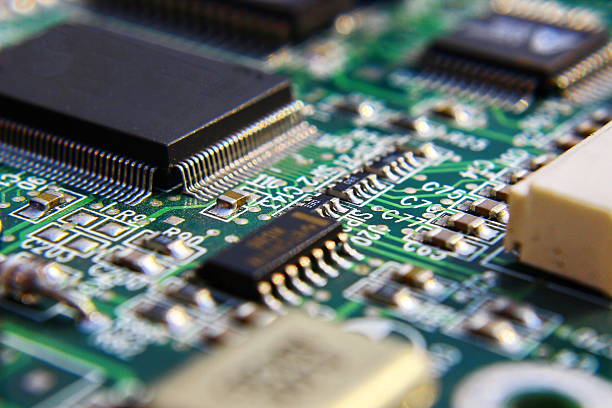

Preventing Tombstoning Solder Joints: Touchpad Electronics’ Commitment to Quality PCB Assembly

When it comes to Printed Circuit Board (PCB) assembly, ensuring the integrity of solder joints is paramount. One common issue that electronics manufacturers face is “tombstoning,” a soldering defect that can compromise the performance and reliability of electronic devices. At Touchpad Electronics, we take quality seriously, and we’ve implemented robust practices to prevent tombstoning solder joints in our PCB assembly processes.

Understanding Tombstoning

Tombstoning is a solder joint defect that occurs when one end of a surface-mount component lifts off the PCB pad during reflow soldering, resembling a tombstone. This defect can lead to poor electrical connections, intermittent functionality, and ultimately, device failure. Tombstoning can be caused by various factors, including temperature variations, uneven solder paste deposition, and component placement issues.

How Does TouchPad Prevent Tombstoning?

At Touchpad Electronics, we are committed to delivering PCB assemblies of the highest quality. Here’s how we prevent tombstoning solder joints in our PCB assembly processes:

1. Precise Solder Paste Application

We invest in state-of-the-art solder paste printing equipment that ensures precise and consistent solder paste deposition. This minimizes the chances of uneven solder distribution, a common cause of tombstoning.

2. Optimal Reflow Soldering Profiles

Our experienced technicians meticulously create and monitor reflow soldering profiles. By carefully controlling the temperature and heating rates, we ensure that components are evenly heated, reducing the risk of tombstoning.

3. Component Placement Accuracy

Our advanced pick-and-place machines are equipped with vision systems that guarantee precise component placement. Components are accurately aligned and secured to their designated pads, minimizing any potential for tombstoning.

4. Quality Solder Materials

We use high-quality solder materials that are specifically chosen for their reliability and performance. These materials have been extensively tested to resist defects like tombstoning.

5. Rigorous Inspection and Testing

Each PCB assembly goes through a series of rigorous inspections and tests, including visual inspection, X-ray inspection, and functional testing. This multi-layered approach allows us to identify and rectify any tombstoning issues before the final product is shipped.

6. Continuous Improvement

We believe in continuous improvement. Our team regularly reviews and updates our assembly processes to incorporate the latest industry best practices and technological advancements in tombstoning prevention.

Partner with Touchpad Electronics

When you choose Touchpad Electronics for your PCB assembly needs, you’re partnering with a company that prioritizes quality and reliability. Our dedication to preventing tombstoning solder joints is just one aspect of our comprehensive approach to delivering top-tier electronic assemblies.

Whether you’re developing prototypes or planning large-scale production runs, you can trust us to provide PCB assemblies that meet the highest industry standards. Contact us today at https://touchpadelectronics.com/contact-us/ to discuss your project and discover how Touchpad Electronics can be your trusted partner in electronic manufacturing.